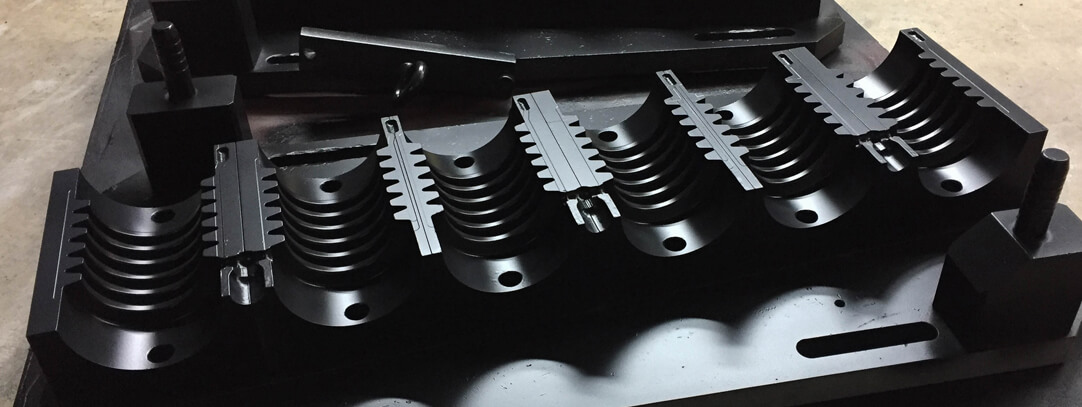

Non-Stick Surface Coatings

Secoa Metal Finishing is renowned for its expertise in developing high-performance, non-stick surface coatings. We have engineered our range of non-stick coatings to meet the demanding needs of various industries and provide surfaces with exceptional resistance to adhesion and wear. With a strong focus on custom non-stick coatings, we tailor solutions to specific client requirements and ensure optimal performance and longevity. Our commitment to quality and innovation places us at the pinnacle of coating technologies, offering unparalleled service and technical proficiency. Let Secoa Metal Finishing be your partner for non-stick surface coatings that enhance efficiency and productivity through the superior application of non-stick technologies.

INDUSTRIAL NONSTICK COATINGS ENGINEERED FOR LOW FRICTION & HIGH PERFORMANCE

Secoa Metal Finishing uses high-spec coatings and advanced industrial finishing equipment to deliver premium nonstick coating options. Specially engineered to minimize friction, our custom nonstick coatings help components move together smoother and more efficiently, minimizing wear-and-tear damage while substantially increasing service life.

CUSTOM NONSTICK COATINGS OPTIONS OPTIMIZED FOR YOUR COMPONENTS

Turn to Secoa Metal Finishing for all of your nonstick and release coatings! We have a diverse selection of custom coating options available in both powder and dispersion forms. Our advanced release coatings include various fluoropolymers, silicones and other specially engineered chemistries.

The Benefits of Our Premium Nonstick Coatings: Minimum Friction, Maximum Service Life

Low-friction coatings allow machine parts to perform cleanly and efficiently without the addition of dirt-attracting lubricants. Our advanced industrial coatings also allow machines to operate consistently, minimizing the potential for component failure due to corrosion, even after long periods of inoperation.

The application of these custom engineered coatings offers design versatility when it is not feasible to utilize traditional lubricants. Other advantages include the elimination or reduction of noise, as well as increased energy efficiency resulting from a reduced coefficient of friction.

Non-stick coatings don’t just reduce friction and adhesion, they can also be used as a protective barrier, shielding your valuable industrial components from wear, rust and corrosion. The custom nonstick coatings we offer protect against UV light, water, corrosive chemicals and other damaging agents.

If you have a project that requires the application of a non-stick coating, Secoa Metal Finishing can get the job done. We use the industry’s highest-spec coatings and most advanced manufacturing equipment to deliver the high-caliber results your business deserves while keeping our prices competitive through in-house efficiency.

We Offer a Range of Custom Engineered Nonstick Coatings

FluoroClad 5

A water-based dispersion (wet spray) four-coat system that employees a titanium reinforced matrix that is designed for use as a mold release. It is especially effective in applications where non-stick and cleanability is desired. This coating is designed for both industrial applications and where food contact is involved. FC 5 is especially noted for its excellent durability and hot hardness capabilities. The maximum continuous temperature resistance of 500° F (260° C). This coating system complies with the FDA code of federal regulations referenced in CFR title 121 subsections 175.300. It is also compliant with California prop 65.

FluoroClad 6

A two-coat system designed for a wide range of industrial applications where there is a need for the highest level of release coupled with very good abrasion resistance. Abrasion resistance is due to the very low coefficient of friction exhibited by the coating system. FC 6 has a continuous operating temperature rating of 450° F (232° C). This coating system complies with the FDA code of federal regulations referenced in CFR title 121 subsection 175.300.

FluoroClad 7

A three-coat water based dispersion (wet spray) coating system. FC 7 exhibits enhanced nonstick properties combined with outstanding durability. It has been specially formulated for application to surfaces of cookware, bakeware, and cutlery. The maximum continuous temperature resistance of 500° F (260° C). This coating system complies with the FDA code of federal regulations referenced in CFR title 121 subsection 175.300.

FluoroClad 19

A highly durable two-coat system that exhibits excellent release properties. FC 19 is available as both a wet dispersion coating and a powder coating. Traditionally it is applied as a combination wet and powder, the first coat being a water-based primer and the second coat a powder. However, there is a powder primer specially developed to accompany the top coat. All forms of FluoroClad 19 are compliant with FDA Code CFR Title 121, subsection 175.300 guidelines for food contact.

FluoroClad DL

FluoroClad DL is a unique blend of powder on powder chemistries that results in a superbly durable and flexible coating with applications in many different industrial settings as well as excellent release properties. With the FluoroClad DL product the customer can expect an increased durability, higher temperature resistance (550° F (288° C), with peaks of up to 600° F (315.5° C)) increased chemical resistance (over 1,000 hours (ASTM B-117) Salt Spray) than with traditional fluoropolymers.

FluoroClad SDFC

This is our ceramic reinforced, two coat water based system that was specifically devised to repel slag buildup and weld splatter.

SUPERIOR NONSTICK COATING SOLUTIONS OPTIMIZED FOR INDUSTRIAL EFFICIENCY & PERFORMANCE

Timing and cost are of the utmost importance to our customers, which is why we have invested in cutting-edge coating equipment capable of delivering rapid, consistent product finishing results. We can easily ramp up production to coat large quantities of components in a very short period of time, enabling us to complete high-volume orders with no commensurate loss of quality.

Our premium nonstick coating services are suitable to enhance the production equipment used in many different industries and applications. If you’re not sure what type of coating is going to work best on your product, give us a call and we’ll be happy to advise you.