A Brief History of Epoxy

Epoxy resins have been around for nearly a century. They were first developed in the early 1930s and commercialized circa 1946. They quickly became popular in the aerospace industry, then for military applications. Demand continued to grow as epoxy’s many benefits became more well-known, and it remains a common coating choice to this day.

Benefits of Epoxy Powder Coating

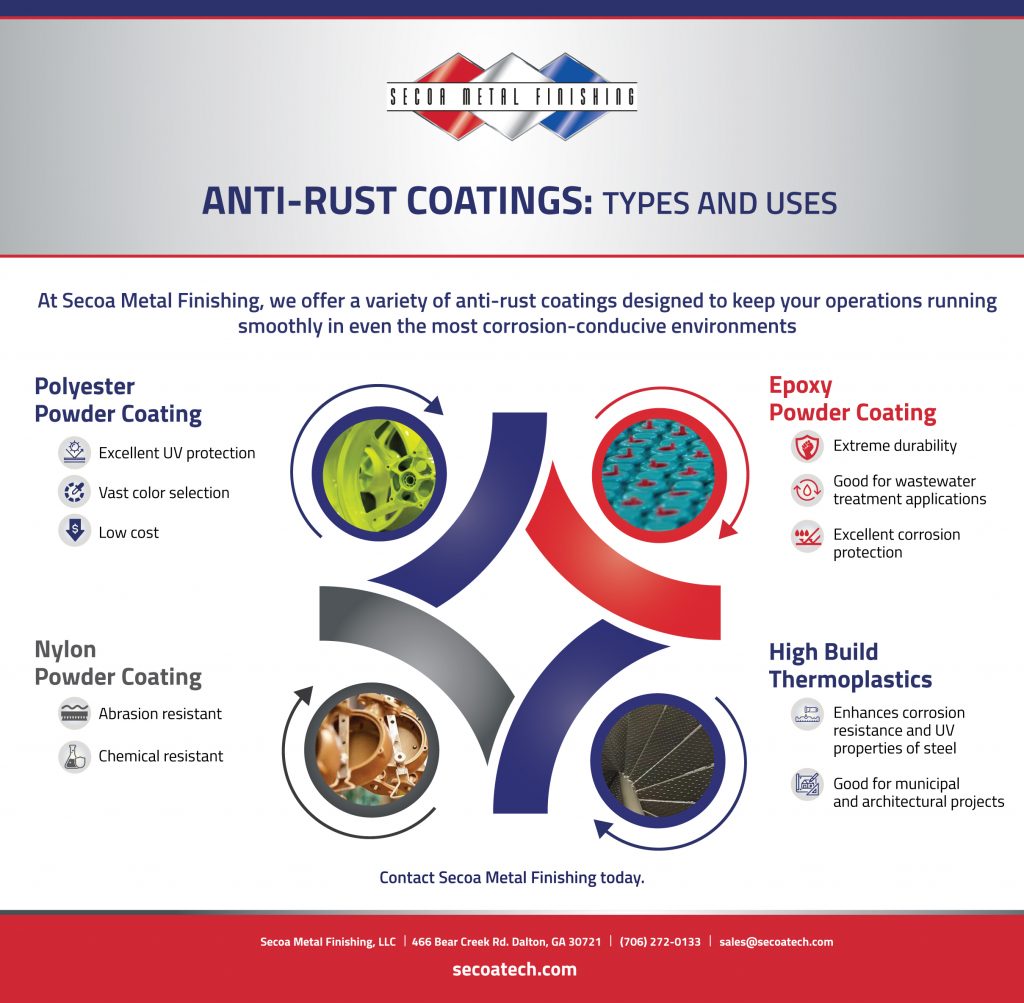

Epoxy powder coating offers a variety of advantages. It is extremely durable, and has high chemical and corrosion resistance. It also has excellent electrical insulation capabilities and adhesion properties. Epoxy will bond well to most surfaces and last for a long time, even in harsh environments.

Common Applications

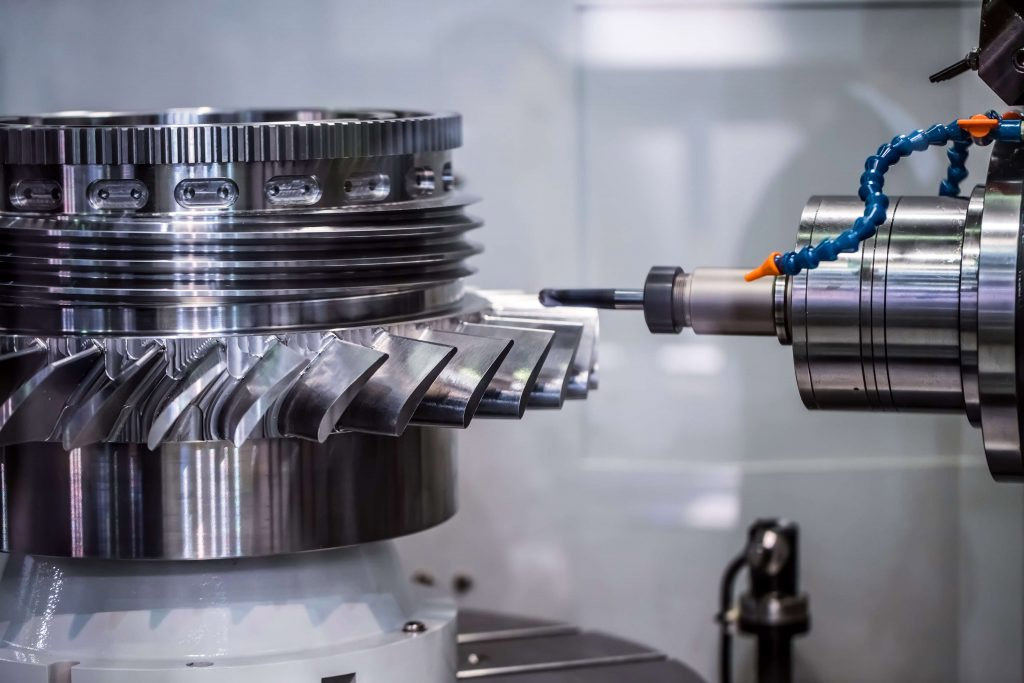

Due to its versatility, epoxy powder coating is used for a vast range of applications in all kinds of different industries, including:

- Oil and Gas: Thanks to their high chemical resistance and overall durability, epoxy powder coatings can be used to coat pipes and valves for use in the oil and gas industry.

- Automotive: Epoxy coatings have many uses in the automotive industry. Their durability makes them good for coating underbody parts and components, while their insulation properties make them good for motor-based applications.

- Aerospace: Epoxy powder coatings have been used for aerospace applications since the 1950s, and they continue to be used in the industry to this day.

- Industrial Manufacturing: Due to its high corrosion resistance and ability to withstand harsh conditions, epoxy powder coating is frequently used in industrial manufacturing operations.

Contact Secoa Today

Epoxy powder coating has been a sought after coating method for decades, and will continue to be so long into the future. If you need a reliable epoxy powder coating supplier, contact Secoa Metal Finishing today. You can reach us by phone at (706) 383-2893 or send an email to sales@secoatech.com.

At Secoa, we know that rust will ruin a coating job. That’s why our specialty finishing services include metal preparation. Proper surface preparation is an essential part of the coating process; removing contaminants (such as rust) before applying powder coating helps ensure a pristine finish.

Secoa offers multiple metal preparation services, including blasting and burn-off. Thanks to our top of the line equipment, we have the capability to strip and prepare a wide range of both ferrous and non ferrous substrates, including iron, steel, aluminum, magnesium, titanium, and more. We always remove rust from a surface before applying a coating in order to achieve the highest quality results.

At Secoa, we know that rust will ruin a coating job. That’s why our specialty finishing services include metal preparation. Proper surface preparation is an essential part of the coating process; removing contaminants (such as rust) before applying powder coating helps ensure a pristine finish.

Secoa offers multiple metal preparation services, including blasting and burn-off. Thanks to our top of the line equipment, we have the capability to strip and prepare a wide range of both ferrous and non ferrous substrates, including iron, steel, aluminum, magnesium, titanium, and more. We always remove rust from a surface before applying a coating in order to achieve the highest quality results.

If you want to learn more about eco-friendly metal finishing, contact Secoa Metal Finishing at (706) 383-2893 or

If you want to learn more about eco-friendly metal finishing, contact Secoa Metal Finishing at (706) 383-2893 or